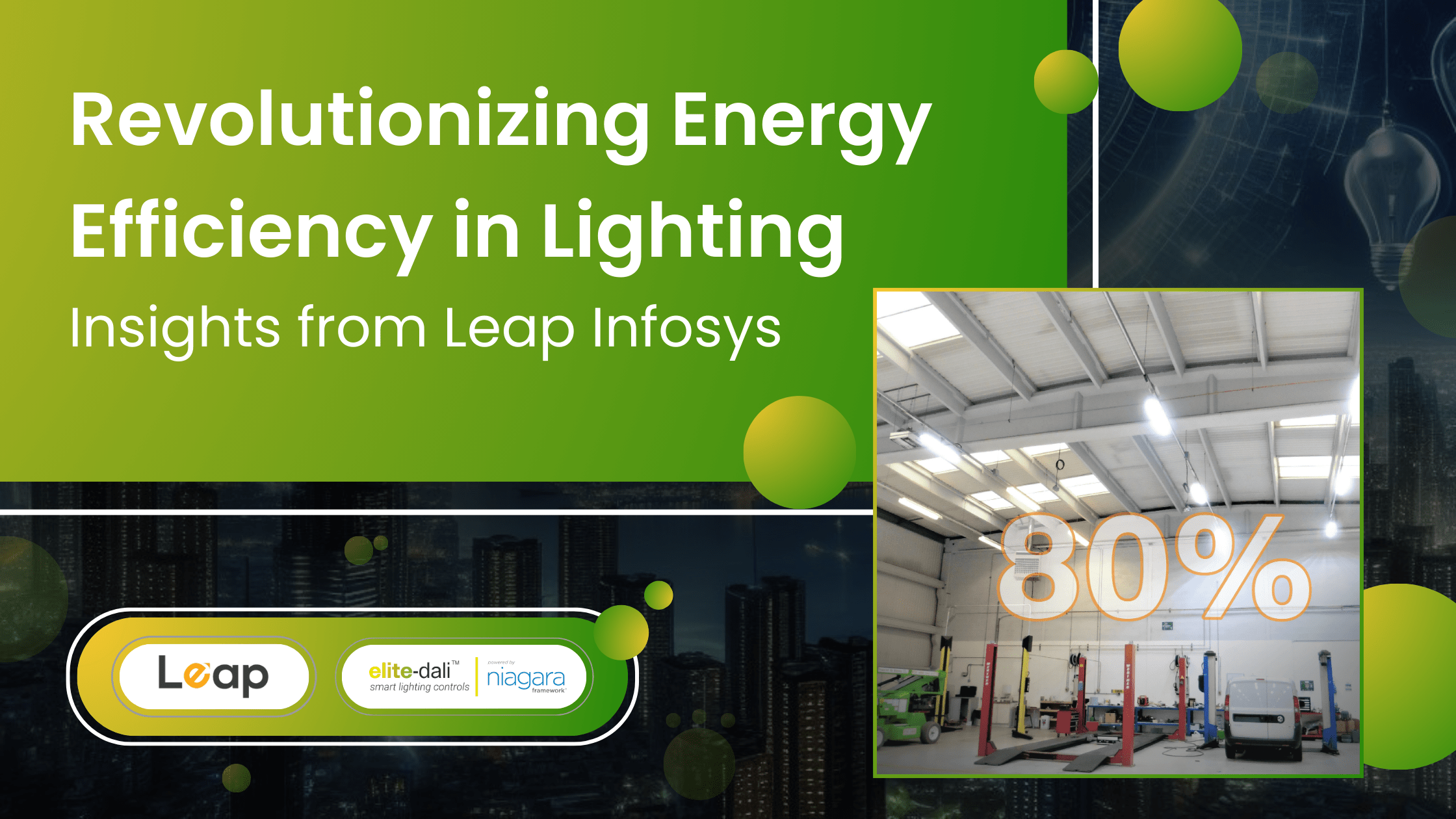

Revolutionizing Energy Efficiency in Lighting for Industrial Facilities: Insights from Leap Infosys

In our pursuit to uncover significant energy-saving opportunities across large facilities like factories and warehouses, Leap Infosys conducted a detailed survey that revealed a startling inefficiency: nearly appx. 80% of these spaces had artificial lighting switched ON during daylight, even though there was sufficient light levels available, consuming considerable energy.

This surprising observation led us to deeper discussions with stakeholders, who highlighted several key challenges:

Key Challenges Identified

Existing method of switching:

All the facilities use a single control point i.e. switch or MCB for multiple lights, making selective switching impractical. Turning off lights in well-lit areas would also mean darkening essential spaces.

Inadequate and consistent Natural Lighting:

In some instances, while natural light did help, it wasn’t sufficient. Once artificial lights were turned off, the illumination levels dropped significantly, affecting operations.

Operational Feasibility:

Manually managing lighting based on time-of-day and occupancy isn’t practical on a large scale.

Key Survey Findings

Awareness and Limitations:

Most respondents were aware of excessive lighting but faced limitations due to integrated power circuit designs, which prevent selective switching off, thus keeping unnecessary lights on.

Insufficient Illumination:

Areas with sufficient natural light still required artificial lighting because turning them off drastically reduced overall illumination.

Manual Operation Challenges:

The impracticality of manually adjusting lights frequently throughout the day was a common concern among facility managers.

How to Address this

To address these issues, Leap Infosys introduced smart IOT lighting systems equipped with intelligent sensors and adaptive controls. These systems dynamically adjust to ambient light levels, optimizing energy use while maintaining sufficient lighting.

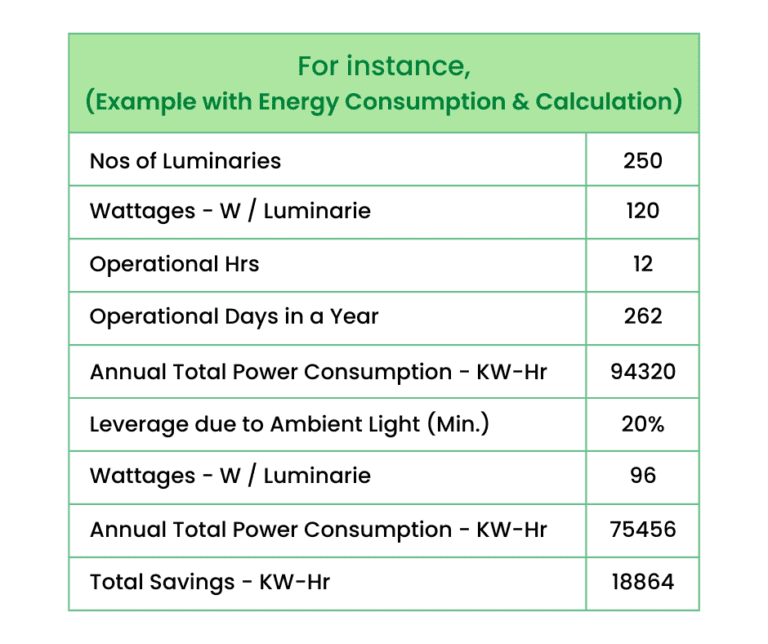

Example of Energy Savings Calculation:

By adopting latest IOT technologies and adaptive controls, businesses can significantly reduce their energy consumption while enhancing operational efficiency.

This transformation isn’t just about cutting costs—it’s a step towards sustainable operational practices that align with global energy conservation goals.